Compound Business

As a manufacturer of colored compounds and resins, we provide products tailored to the needs. Our in-house factory in Kasukabe, Saitama is equipped with the latest facilities and research and development quality control system.

Features

-

feature 01

Technological development capabilities

We have developed our original product "TR Resin" by arranging various resins and additives and utilizing compound technology to meet diverse needs.

-

feature 02

Ability to respond to small-scale production and advanced coloring technology

With its unique production system, high-quality products can be produced quickly even in small quantities. With approximately 20,000 color matching achievements to date, products in various colors can be manufactured.

-

feature 03

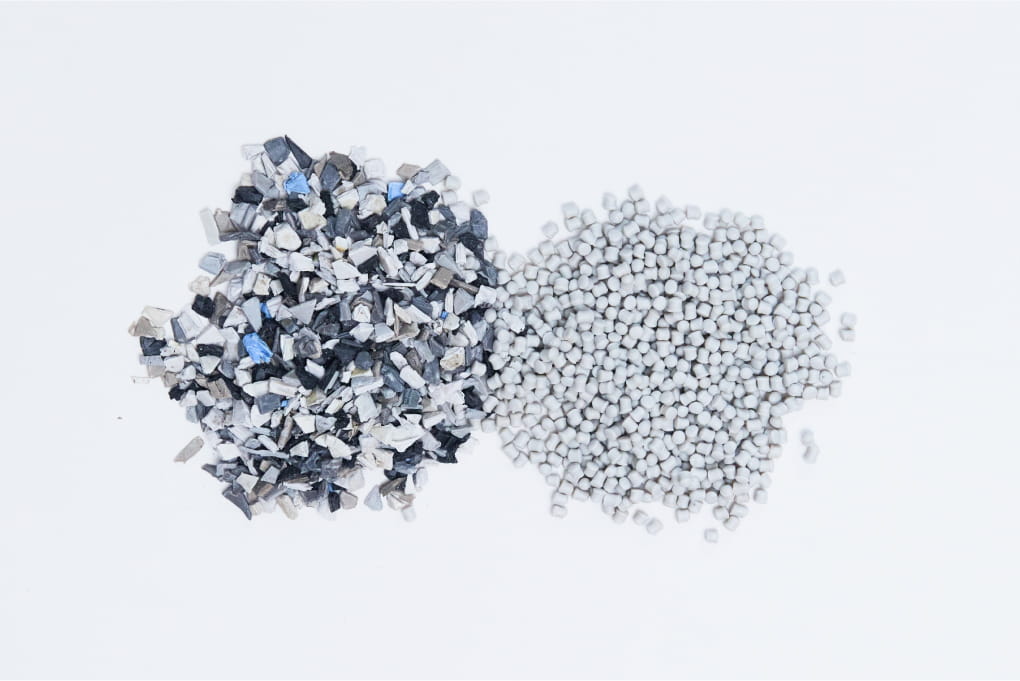

Environmentally friendly materials can also be developed.

The selection of base materials can be made from virgin materials or recycled materials, allowing for the creation of environmentally friendly products.

-

feature 04

A system for creating products that are trusted by customers.

We have two in-house factories in the Kanto region and have established a unique production and quality control system with state-of-the-art facilities.

Quality policy of Takaroku

By utilizing digital technology to improve productivity, strengthening personnel development (education and training), and thoroughly implementing 3S (sorting, organizing, cleaning), we aim to maintain a safe and efficient working environment, and enhance the overall competitiveness and quality of the organization.

Development quality assurance related measuring equipment

| MFR (MI) | Melt indexer |

|---|---|

| Specific gravity | Automatic densitometer |

| Tensile and bending | Stroganoff |

| Izod impact strength | Impact testing machine |

| Hot deformation temperature | HDT testing machine |

| Re-ignition test | Combustion test machine |

| Thermal properties | Ball pressure temperature |

| Moisture content | Moisture meter |

| Electrical characteristics | High resistance meter, low resistance meter |

| Structural analysis | FT-IR |

| Hardness | Digital durometer |

| MFR (MI) | Melt indexer |

|---|---|

| Specific gravity | Automatic densitometer |

| Tensile and bending | Stroganoff |

| Izod impact strength | Impact testing machine |

| Hot deformation temperature | HDT testing machine |

| Re-ignition test | Combustion test machine |

| Thermal properties | Ball pressure temperature |

|---|---|

| Moisture content | Moisture meter |

| Electrical characteristics | High resistance meter, low resistance meter |

| Structural analysis | FT-IR |

| Hardness | Digital durometer |

| Device name | Purpose of use |

|---|---|

| Melt indexer | Measurement equipment for measuring one of the indicators representing the fluidity of resin |

| Specific gravity meter | Device for inspecting whether the processed pellets have the intended specific gravity. |

| Universal testing machine (tensile and bending test) | Typical tests for mechanical properties such as tensile and bending tests can be measured to determine ductility and stiffness. |

| Load deflection temperature measuring instrument | Device for measuring thermal properties. It is possible to evaluate heat resistance under a constant load. |

| Impact testing machine (Charpy Izod) | A device for measuring the strength against impact. It is possible to measure the amount of energy absorbed until the sample is destroyed. |

| Moisture content meter | Measuring equipment that can be measured by the Karl Fischer method. It is possible to measure the moisture content in resin pellets. |

| Ball Pullshe Temperature Measuring Device | Device for measuring thermal properties. Evaluation is possible based on the amount of indentation by a pressure needle in a heated state. |

| Durometer (A hardness, D hardness) | Measuring equipment for evaluating the hardness of rubber and plastic. |

| Surface resistivity | Device used as an indicator for evaluating the conductivity and electrostatic prevention of thin belts. |

| Foreign object inspection machine | A device that detects and inspects foreign objects on pellets or plates using a camera. It can measure the size and quantity of foreign objects, and also create histograms. |

| CCM(Computer Color Matching) | When creating the desired color, the device calculates what composition will produce a similar color based on past formulations, and can also measure the hue and brightness. |

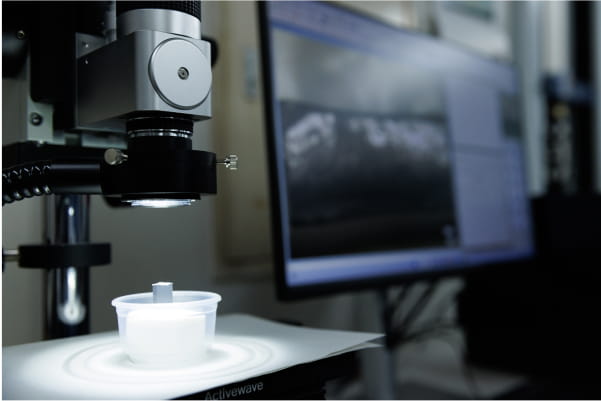

| Digital microscope | A device that allows for the magnified observation of foreign objects or pellets. The observation magnification ranges from x25 to x2500. |

contact us!

If you have any questions or concerns regarding the product, please feel free to contact us.